40 pressure vacuum breaker diagram

June 10, 2016 - The most basic form of protection is the presence of an air gap in between the possible source of contamination and access to the plumbing system The atmospheric vacuum breaker consists of a check valve member and an air vent that is normally closed when the device is pressurized A hose connection ... Vacuum Breaker Valve 720A has all Bronze Body and Bonnet Construction With a Maximum Water Pressure 150 Psi. An Ideal Choice for Industrial and Commercial Applications

The Model 420 Pressure Vacuum Breaker may be installed outdoors only if the device is protected against any freezing conditions. Warning: Do not block air vent opening with insulation. Exposure to freezing conditions will result in improper func-tion or damage to the device. The installation location must be kept above 32°F.

Pressure vacuum breaker diagram

Diagram of Atmospheric Vacuum Breaker in both working states. It is usually constructed of brass and resembles a 90-degree elbow with a hood on its top to allow air to enter the water system if a siphon attempts to form. Inside this elbow is a poppet valve that is held "up" by the water pressure ... October 12, 2019 - Chlorine And Soda Ash Sodium ... Pressure Tanks Wellness · How To Design A Pex Water Manifold Just Needs Paint Diy Plumbing Pex Plumbing Plumbing Installation · How To Fix A Leaky Outdoor Faucet The How To Self Learning Videos Online · Everbilt 3 4 In Hose Bibb Vacuum Breaker Vacbfpz4eb ... Is your pressure vacuum breaker leaking or malfunctioning? It may be in need of repair. The Watts - Ames experts walk you through this quick fix, including t...

Pressure vacuum breaker diagram. Series 800M4QT Anti-Siphon Pressure Vacuum Breakers prevent the reverse flow of polluted water from entering into the potable water supply due to backsiphonage. It consists of bronze body construction, silicone rubber check valve disc, plastic check valve seat, stainless steel springs, a bonnet wit Fixing RV Plumbing issues can be expensive AND a hassle. Here's how we protect our RV from water pressure issues.🛒 Visit Our RV Gear & Travel Store: https:/... After the installation of a Model 720A Pressure Vacuum Breaker has been completed, place the unit in service as follows: 1. Start with both shut-off valves and test cocks closed. Open the inlet shut-off valve until the Pressure Vacuum Breaker is completely pressurized. 2. A brief discharge from the air vent may occur while the device is ... Vacuum Breaker.) Purpose of Test: (see diagram next page) To test the Air Inlet and the Check Valves for proper performance. Test Air Inlet: The Air Inlet should be tested to verify opening above 1 psi. 1. Remove Canopy from top of Vacuum Breaker to expose Air Inlet. 2. Install Sight Tube at Testcock #2 (as shown). 3.

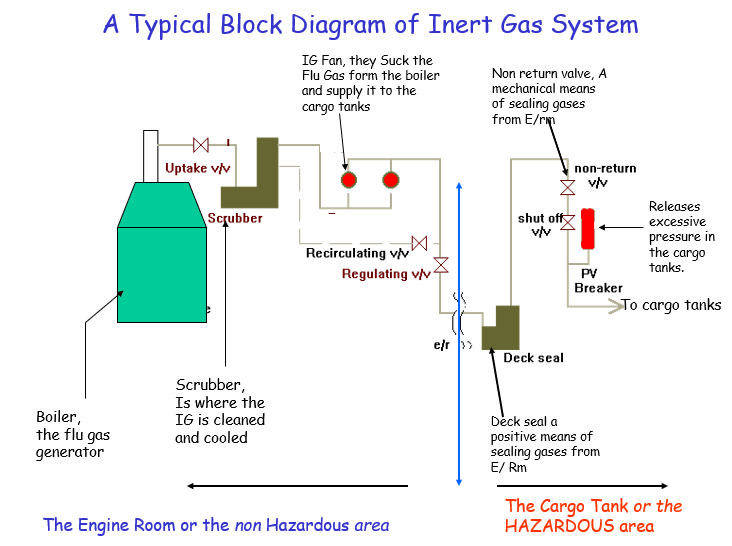

The schematic diagram of a typical PV breaker is shown below. as you can see from that diagram it just consists of a an open section of the pipe which would have been open to the atmosphere but for the liquid which is present in the container. Before opening the pressure vacuum breaker assembly, close the isolation valve, the outlet shutoff valve, and the inlet shutoff valve in that order. Open test cock #2 to release pressure. Then remove the assembly cover. One common cause of pressure vacuum breaker malfunction is debris in the system, particularly the poppet or check assembly. The Model 720 and 720A are pressure vacuum breaker assemblies. Production began approximately 1975 under the SMR name. Around 1978 it was sold to the Neptune Meter Co. In 1984 Wilkins regulator bought the rights to produce this assembly. The assembly is of bronze body construction. The check spring is contained when the bonnet is removed. A leading manufacturer of water quality solutions. Water safety, flow control, backflow prevention, drainage. Learn more about our products!

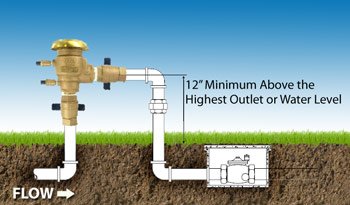

A pressure vacuum breaker (PVB) is a type of backflow prevention device, used to keep non-potable (or contaminated) water from entering the water supply. A PVB is similar to an atmospheric vacuum breaker (AVB), except that the PVB contains a spring-loaded poppet. Pressure Vacuum Breaker assemblies shall be installed a minimum of 12" (300mm) above the highest downstream outlet, and the highest point in the downstream piping. The assembly shall be rated to 150psi working pressure and water temperature from 32°F to 140°F. The assembly shall 1 in. Pressure Vacuum Breaker. 3/4 in. Lead Free Bronze FIP Pressure Vacuum Breaker. 3/4 In Lead Free Anti-Siphon Pressure Vacuum Breaker Backflow Preventer with Quarter Turn Shutoff And Tee Handles. 3/4 in. Reduced Pressure Backflow Preventer, Lead Free, Black. Price. Add to Cart to See Price. $11266. $14746. $23900. November 29, 2013 - The Capital Regional District (CRD) is the regional government for 13 municipalities and three electoral areas on southern Vancouver Island and the Gulf Islands, serving more than 425,500 people. Guided by its Board, the CRD works collaboratively to build a vibrant, livable and sustainable region.

Pressure vacuum breaker assemblies (PVBA) are the most commonly used and least expensive type of whole-system backflow prevention valve. These assemblies are easy to install, maintain, and repair. Some models of pressure vacuum breaker assemblies include built-in freeze protection valves.

The Vacuum Breaker functions like a simple check valve. Outside air is allowed to enter the system through the air inlet. However, when steam or water tries to escape, the vacuum breaker closes off tightly. Vacuum Breaker Installation. The unit must be installed in a vertical position and should be placed at the highest point in the system.

Vacuum circuit breakers are employed for outdoor applications ranging from 22kV to 66kV. Even with limited rating say 60 to 100MVA, they are suitable for the majority of applications in rural areas. The working of Vacuum circuit breakers is briefly explained below,. When the breaker operates, the moving contact separates from the fixed contact and an arc is struck between the contacts.

Vacuum Breakers. Designed for use in health hazard cross connections and continuous pressure applications where the water enters the equipment at or below its flood rim. Provides protection against backsiphonage incidents only. Applications include irrigation systems, firelines, and industrial process water systems.

A pressure vacuum breaker will automatically isolate the fresh water supply in various ways should the supply pressure drop of cease altogether. PVBs utilize a spring loaded, poppet type valve to isolate fresh water supplies. This valve is designed to be pushed open by normal system supply pressures allowing water to flow to the destination ...

When unwanted vacuum conditions occur at the higher elevation points it is possible that a vacuum breaker may be introduced in to the system. In Pipe Flow Expert the vaccum breaker can be modelled by using an End Pressure and a Demand In-Flow as is shown in the following diagram. Essentially the system is split in to two separate systems.

Pressure Vacuum Breakers An anti-siphon pressure vacuum breaker shall be installed where indicated on the plans to prevent the back-siphonage of contaminated water. This assembly is not to be used where there is a possibility that a back pressure condition may devel-op. The assembly will incorporate an acetal bonnet with silicone

Free delivery on millions of items with Prime. Low prices across earth's biggest selection of books, music, DVDs, electronics, computers, software, apparel & accessories, shoes, jewelry, tools & hardware, housewares, furniture, sporting goods, beauty & personal care, groceries & just about anything else.

Series 765 Pressure Vacuum Breakers are designed to be installed to provide protection against back siphonage of toxic or non-toxic liquids. They feature a durable bronze body and a check valve and air opening port in one assembly. Maximum Working Pressure: 150psi (10.3 bar).

Read more First Friday Fun Swim Join us for FUN every First Friday Night of the month · A healthy city must have a healthy downtown that is welcoming and appealing to pedestrians that come to shop, work and play. It is critical that the frontages and uses of buildings are oriented toward creating ...

Watts Vacuum Breakers. Watts Series 008, LF008, 008PC, LF008PC Anti-Siphon, Anti-Spill Vaccum Breaker Repair Kits 3/8"- 1" Watts Series 800M, 800CM Pressure Vacuum Breaker Compact Model Repair Kits 1/2" and 3/4" Watts Series 800M4, LF800M4, 800M4FR, LF800M4FR Pressure Vacuum Breaker Compact Model Repair Kits 1/2"-2"

Redundant Anti-Siphon Diagram. Redundant Anti-Siphon Capability: Combined use of Relief Valve & Vacuum Breaker. An engineering firm recently specified two seemingly unrelated valves to provide redundant siphon prevention in a ferric chloride piping system.

This FYI document outlines the proper use of the vacuum breaker anti-siphon system as used in water distribution system. Two drawings are provided to demonstrate possible piping configuration.

800M4QT. ×. Anti-Siphon Pressure Vacuum Breaker Backflow Preventers. Series 800M4QT Anti-Siphon Pressure Vacuum Breakers prevent the reverse flow of polluted water from entering into the potable water supply due to backsiphonage. They have a bronze body construction, silicone rubber check valve disc, plastic check valve seat, stainless steel ...

Vacuum Breaker 6 12" Min. 1 7 7 12" Min. C-14 Recommended Piping Practices for Steam Heating Coils 1. 24" minimum if safety drain is used. 2. Safety drain is used if steam supply is modulated and the condensate system is pressurized or overhead. Armstrong's pumping traps or Posi-Pressure Control system provides additional protection or may ...

Download the Repair and Installation Manual for Febco 765 Pressure Vacuum Breaker. Download the Blowout Instruction Sheet for Febco 765 Pressure Vacuum Breaker. Need help determining the size of you 765? Sizing and ordering the bonnet / poppet repair kits can be done at our online store:

The Toro PVB (Pressure Vacuum Breaker) is designed to prevent backflow of contaminated water into the potable water system due to back-siphoning conditions only. This device should not be installed indoors or where backflow due to back pressure may occur. Installation of this device should conform to local building and plumb-ing codes as they ...

A pressure vacuum breaker consists of a check device, or check valve, and an air inlet that is vented to the atmosphere (open-air). The check valve is designed to allow water through and keep the air inlet closed during normal conditions. When the air pressure is greater than the water pressure, the vented chamber opens and breaks the suction ...

Mankenberg – Self-acting Control Valves optimum and specific solutions from standard up to customized special valves

Accessibility Report · Filename: · 3_Pressure_Vacuum_Breaker_Backflow_Prevention_Assembly_(PVB)_(Standard_ASSE_1020).pdf · Report created by: · Organization: · Summary · The checker found no problems in this document · Needs manual check: 2 · Passed manually: 0 · Failed manually: 0

Measure the length of the small piece of pipe that will go between the pressure-vacuum breaker and the outlet 90-degree elbow. Cut and glue the pipe and 90-degree elbow to the pressure-vacuum breaker adapter. Glue the Vertical Pieces Glue the vertical pieces straight down into the fittings.

Vacuum Breaker.) Purpose of Test: (see diagram next page) To test the Air Inlet and the Check Valves for proper performance. Test Air Inlet: The Air Inlet should be tested to verify opening above 1 psi. 1. Remove Canopy from top of Vacuum Breaker to expose Air Inlet. 2. Install Sight Tube at Testcock #2 (as shown). 3.

water hammer. These excessive pressure situations must be eliminated to protect the valve and system from possible damage. 7. Plastic testcock plugs and tethers are provided (loose in box) for areas that require them. Refer to FEBCO literature on PVB freeze protection, "Freeze Protection 765." Series 765 Pressure Vacuum Breakers Sizes: 1⁄

The vacuum breaker should not be subjected to continuous pressure for more than twelve (12) hours. Note: This device should not be installed in a concealed or inaccessible location, nor where the venting water from the device during its normal functioning may be deemed objectionable. EN

PRESSURE VACUUM BREAKER 765 – Field Testing Procedure Equipment Required For Test: Sight Tube Test Kit (1" clear plastic Sight Tube about 40" long with appro-priate fittings to attach to Testcocks of Vacuum Breaker.) Purpose of Test: (see diagram) To test the Air Inlet and the Check Valves for proper performance. Test Air Inlet: The Air Inlet ...

The new ultra low-profile Magnetic Vacuum Breaker is a valve design to limit negative pressure (vacuum) in a typical tank trailer. The unit employs the already popular "New Gen-eration" design, which can be disassembled, cleaned and repaired without the need for special tools. A permanent magnetic force controls the move-

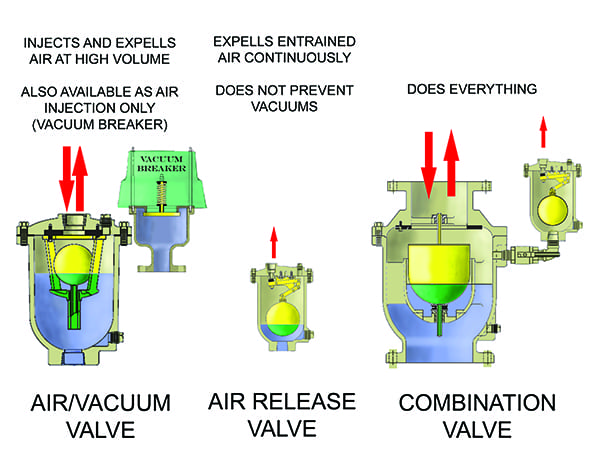

Learn more about different backflow prevention assemblies.

Is your pressure vacuum breaker leaking or malfunctioning? It may be in need of repair. The Watts - Ames experts walk you through this quick fix, including t...

October 12, 2019 - Chlorine And Soda Ash Sodium ... Pressure Tanks Wellness · How To Design A Pex Water Manifold Just Needs Paint Diy Plumbing Pex Plumbing Plumbing Installation · How To Fix A Leaky Outdoor Faucet The How To Self Learning Videos Online · Everbilt 3 4 In Hose Bibb Vacuum Breaker Vacbfpz4eb ...

Diagram of Atmospheric Vacuum Breaker in both working states. It is usually constructed of brass and resembles a 90-degree elbow with a hood on its top to allow air to enter the water system if a siphon attempts to form. Inside this elbow is a poppet valve that is held "up" by the water pressure ...

breaker.PNG)

/product_600x600/product/720a_600x600.aspx?width=600&height=600&ext=.jpg)

0 Response to "40 pressure vacuum breaker diagram"

Post a Comment