40 what is a sipoc diagram

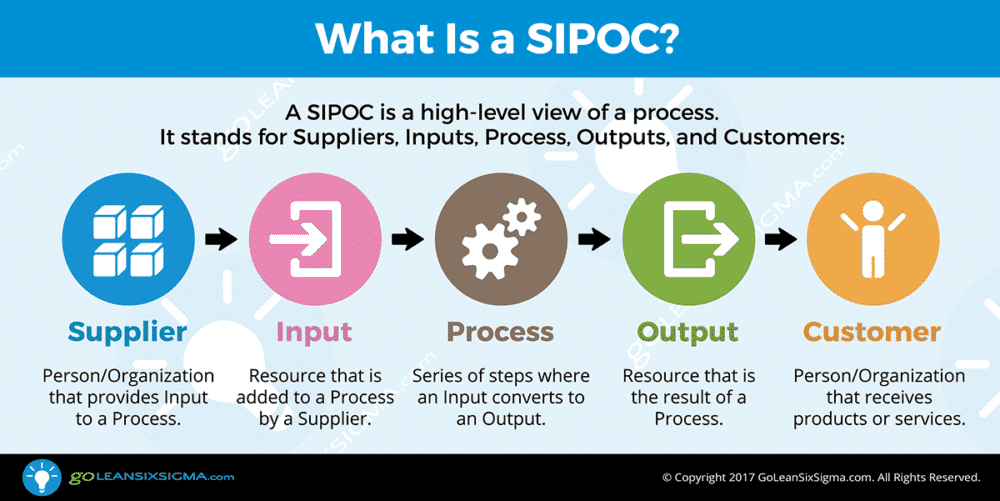

A SIPOC diagram is a form of process mapping. Process mapping is a term used to describe the task of putting a project's goals and, in some cases, detailed steps on how those goals will be accomplished. It's a simple but effective method for ensuring every project team member - as well as executive leadership - are on the same page.

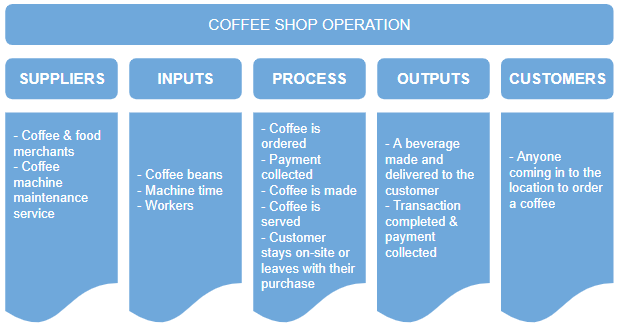

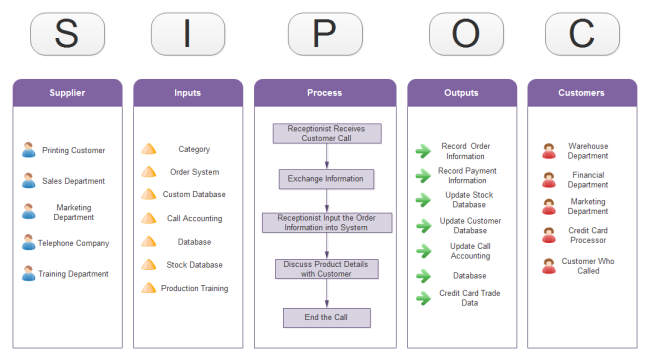

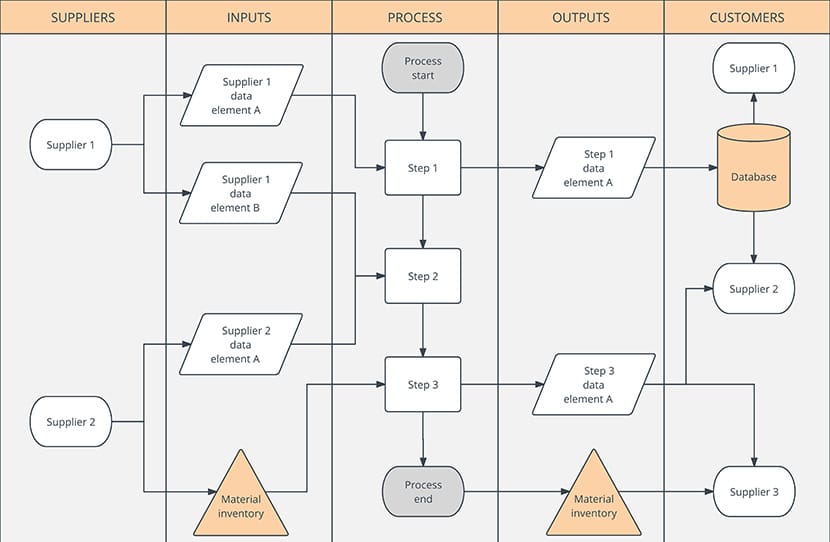

The SIPOC diagram is fairly common among business process experts as a logical way of looking at a process in terms of a series of steps; that converts an input into an output. Inputs come from suppliers, and the outputs go to customers. It helps clearly understand the purpose and the scope of a process.

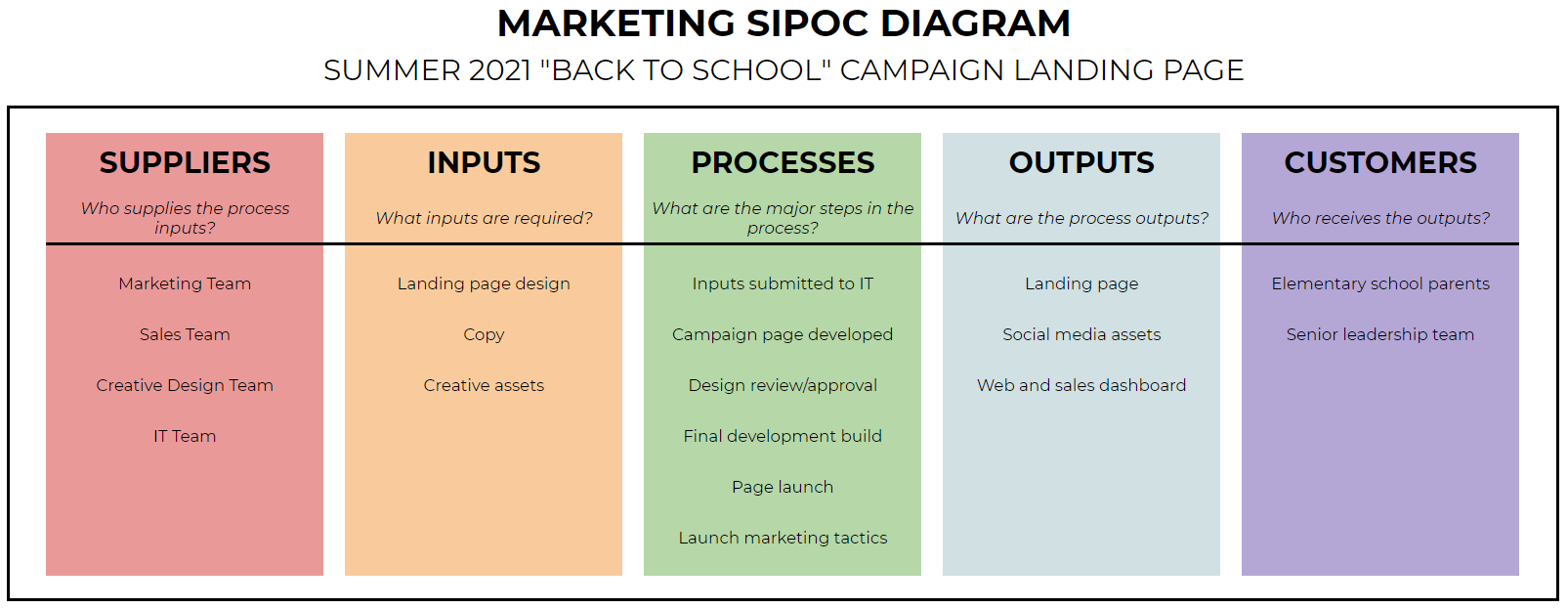

Dec 10, 2021 · Summary. A SIPOC diagram helps map a business process by documenting its suppliers, inputs, process, outputs, and customers. It isn’t meant to provide too much detail, but rather give decision-makers key information about a process. Most often, SIPOC diagrams are used to improve or understand processes associated with customer experience.

What is a sipoc diagram

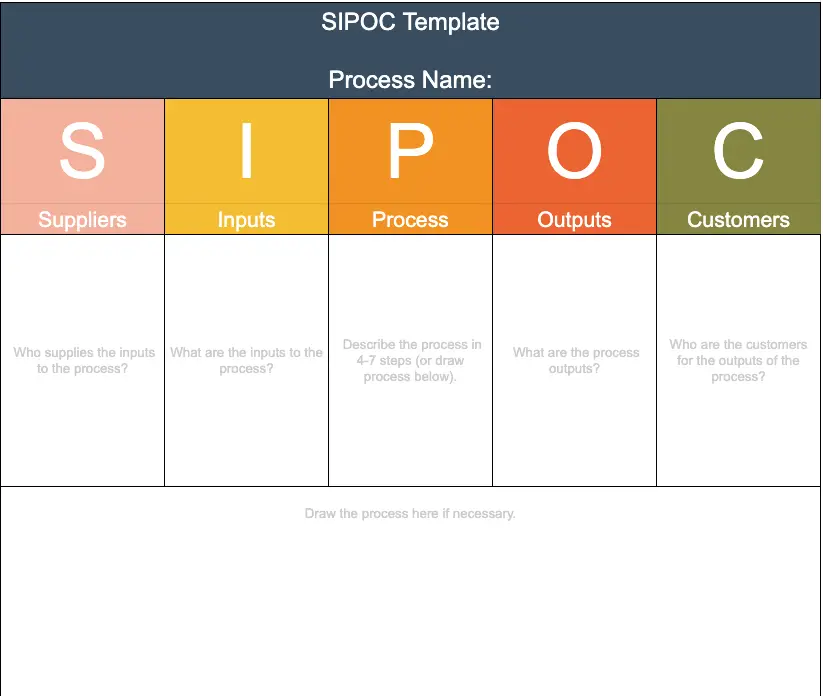

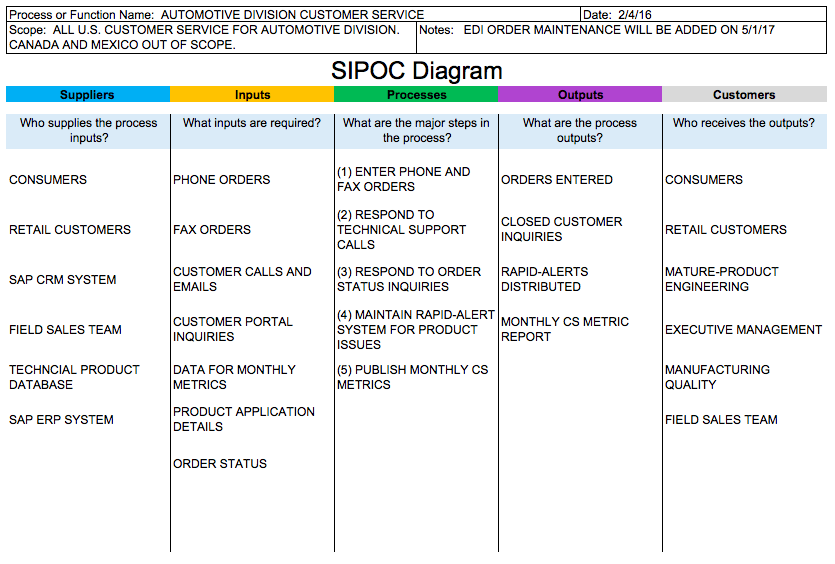

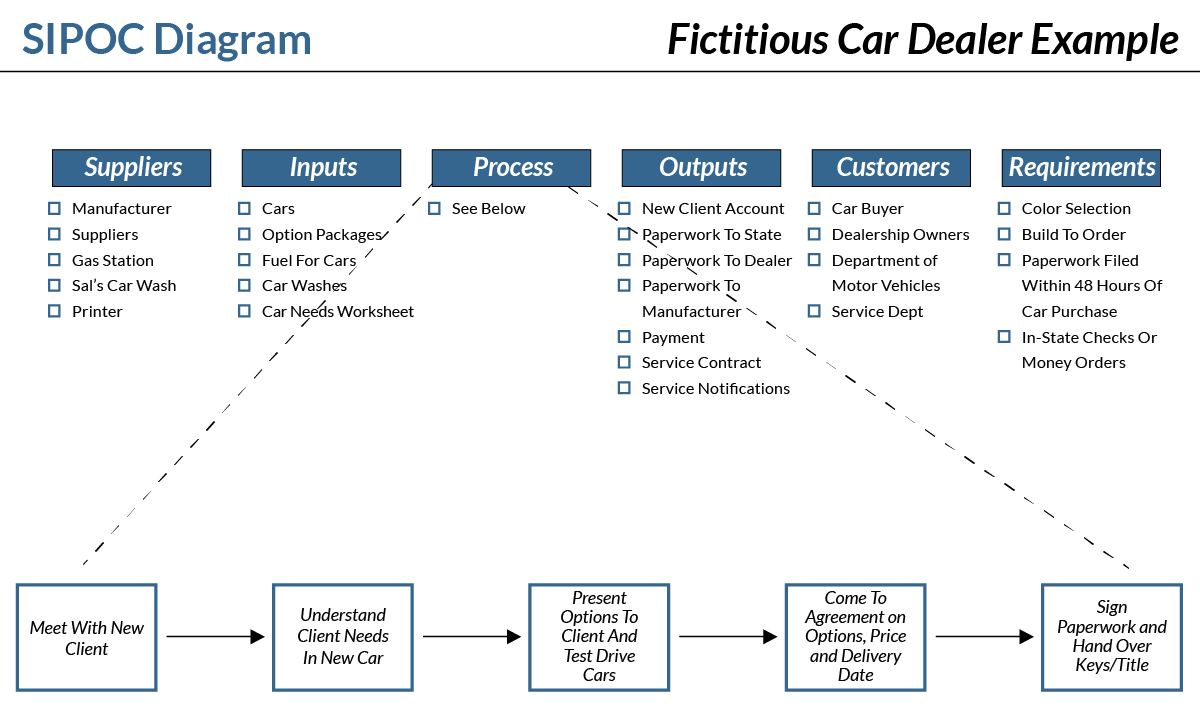

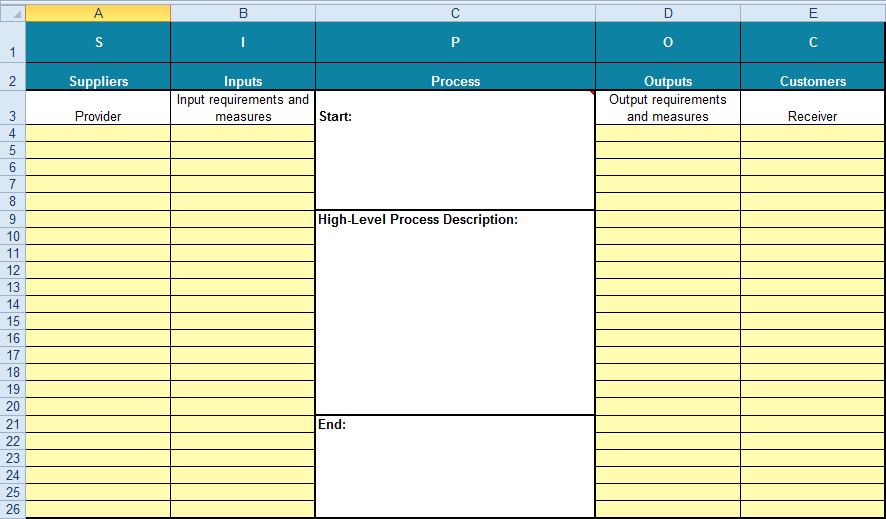

The SIPOC methodology is used to create a SIPOC diagram, like the example detailed below. While it's an empty shell at the moment, I will show you how you can use Process Street's SIPOC Template to fill in the details. SIPOC Template. I'm not one to beat around the bush so to speak.

A SIPOC diagram is a map showing a full process at a high level in no more than 6-8 steps. It identifies the inputs necessary for that process to operate, and who supplies them; and the outputs of the process, and who consumes them. This latter stage is crucial as it identifies who says the outputs are satisfactory.

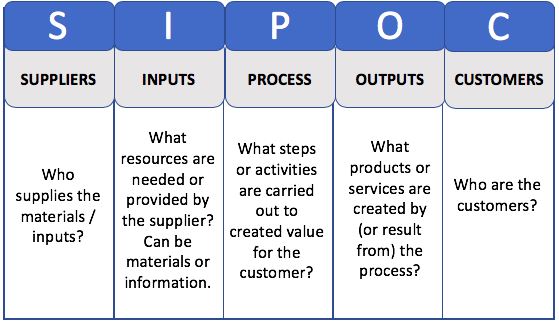

What is a SIPOC Diagram? A SIPOC diagram is a tool used by a process improvement team to identify all relevant elements of a process improvement project before work begins, and helps to define a complex project that may not be well scoped. SIPOC stands for supplier, input, process, output, and customer.

What is a sipoc diagram.

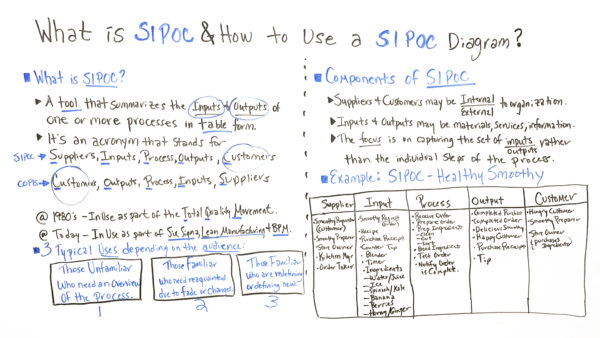

SIPOC is a method to assist in developing the flow on a process map. It is a visual tool for understanding and documenting a process for continuous improvement. In lean six sigma, it is used in the define phase of DMAIC.

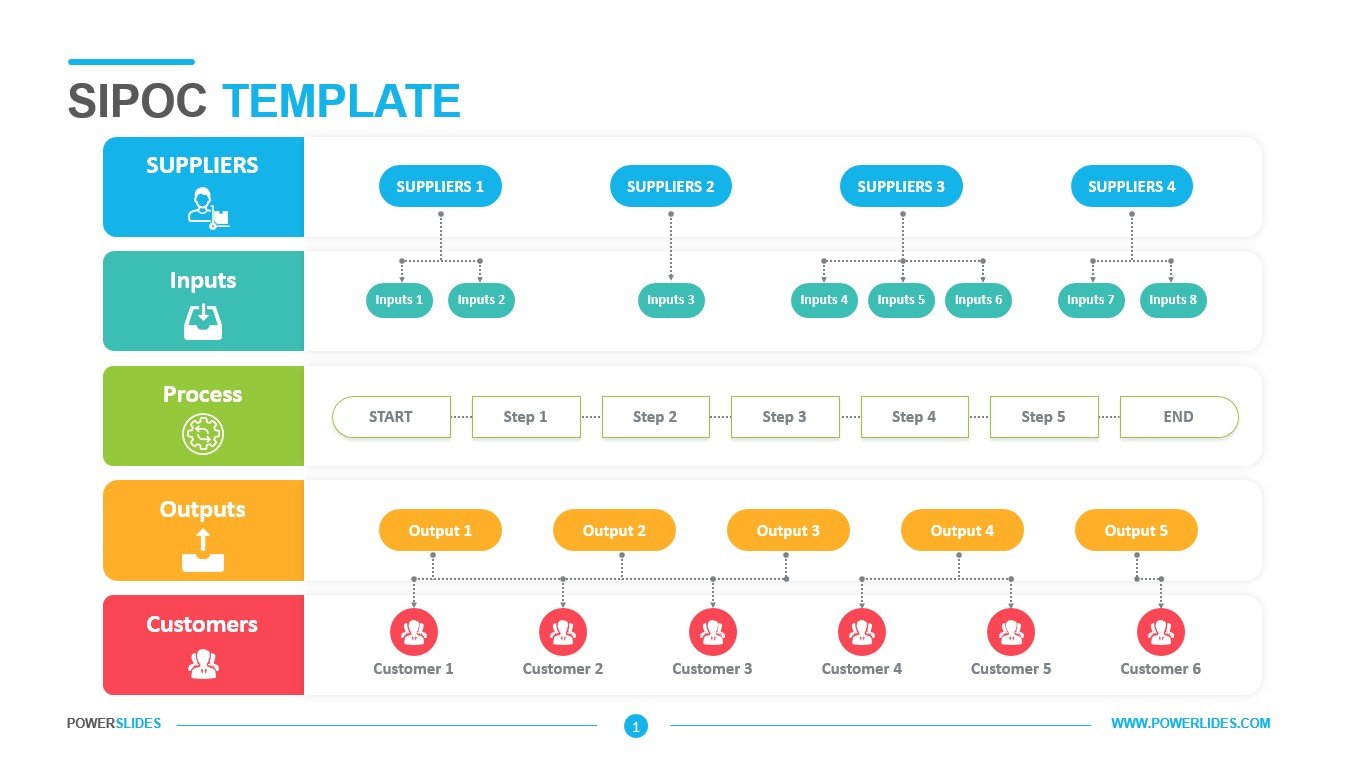

A SIPOC diagram is a high-level view of a process which stands for Suppliers, Inputs, Process, Outputs, and Customers.Every Process starts with Suppliers who provide Inputs to the Process which results in an Output that is delivered to Customers.

Nov 19, 2018 · SIPOC is a tool that summarizes the inputs and outputs of one or more processes in table form. It’s an acronym that stands for Supplies, Inputs, Process, Outputs and Customers. Some organizations use the opposite acronym COPIS, which puts the customer first and illustrates the value of the customer to the organization.

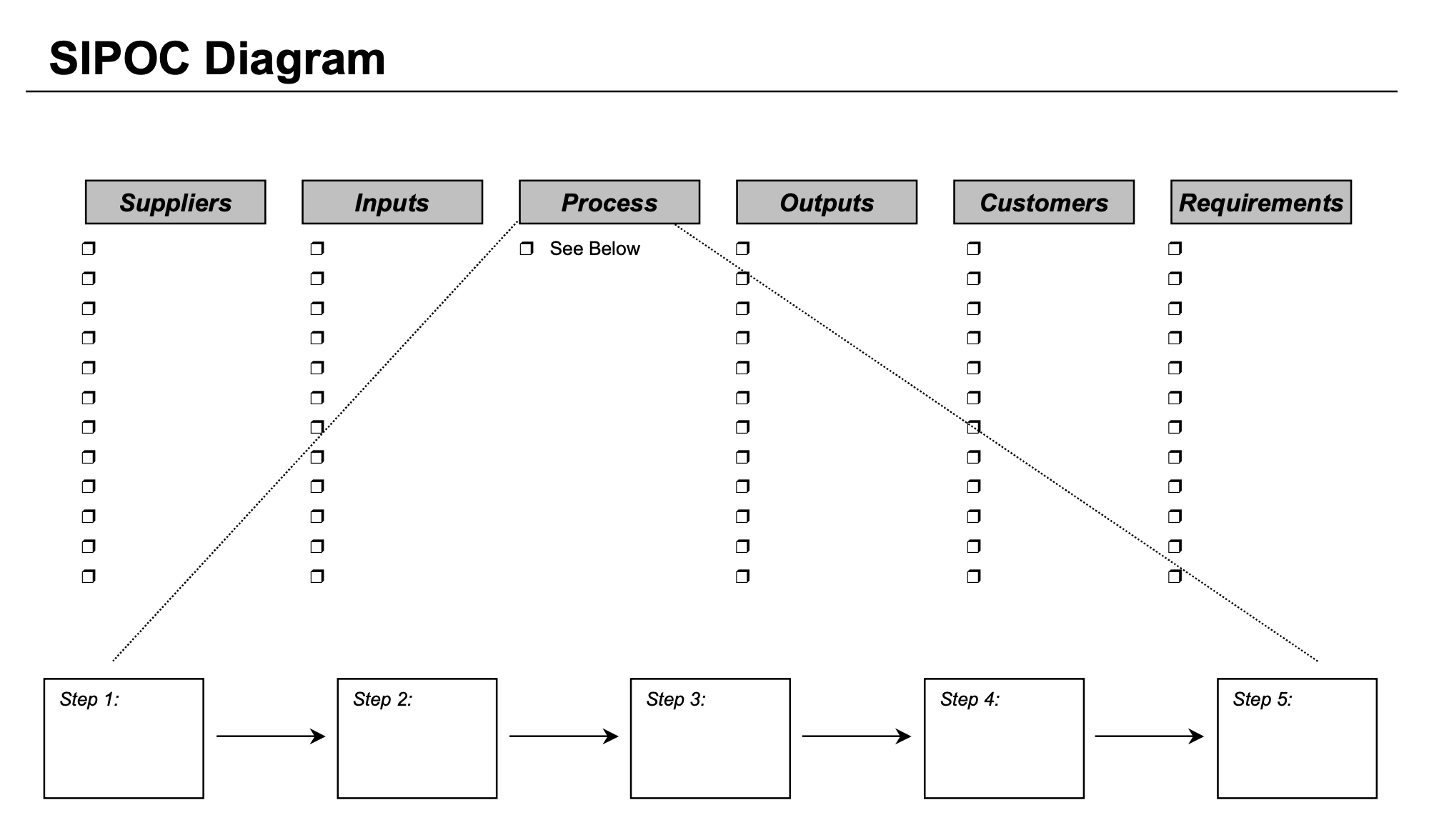

SIPOC+CM Diagram. Quality Glossary Definition: SIPOC diagram. A SIPOC diagram is a data collection tool used by Six Sigma process improvement teams to assist in gathering information about all relevant elements, including suppliers, inputs, processes, outputs, and customers of a process. The +C stands for constraints facing the system, and the +M for the measures to be used.

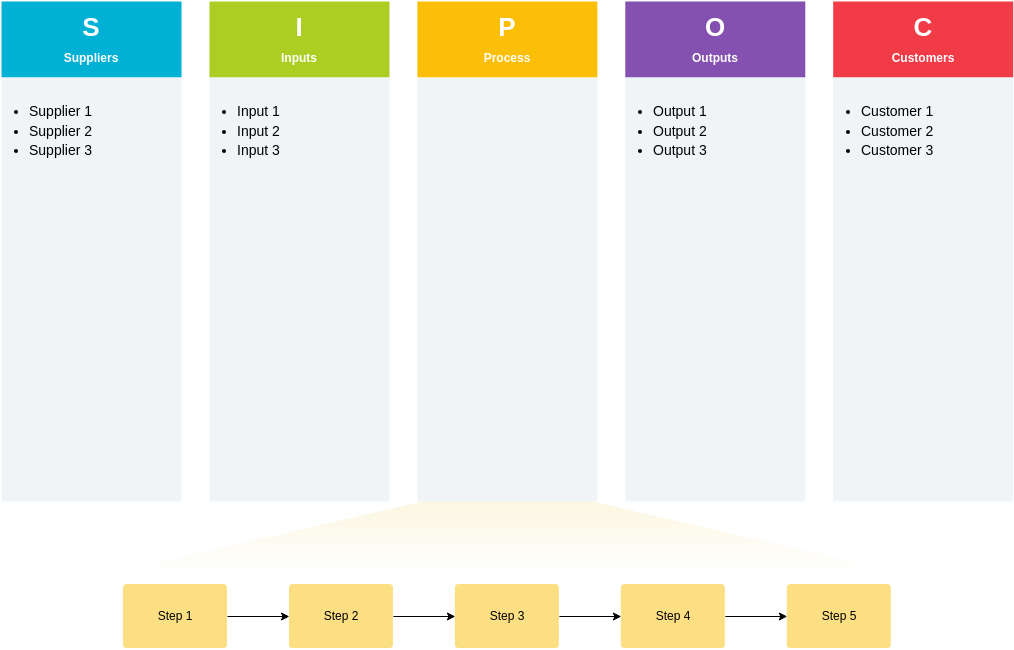

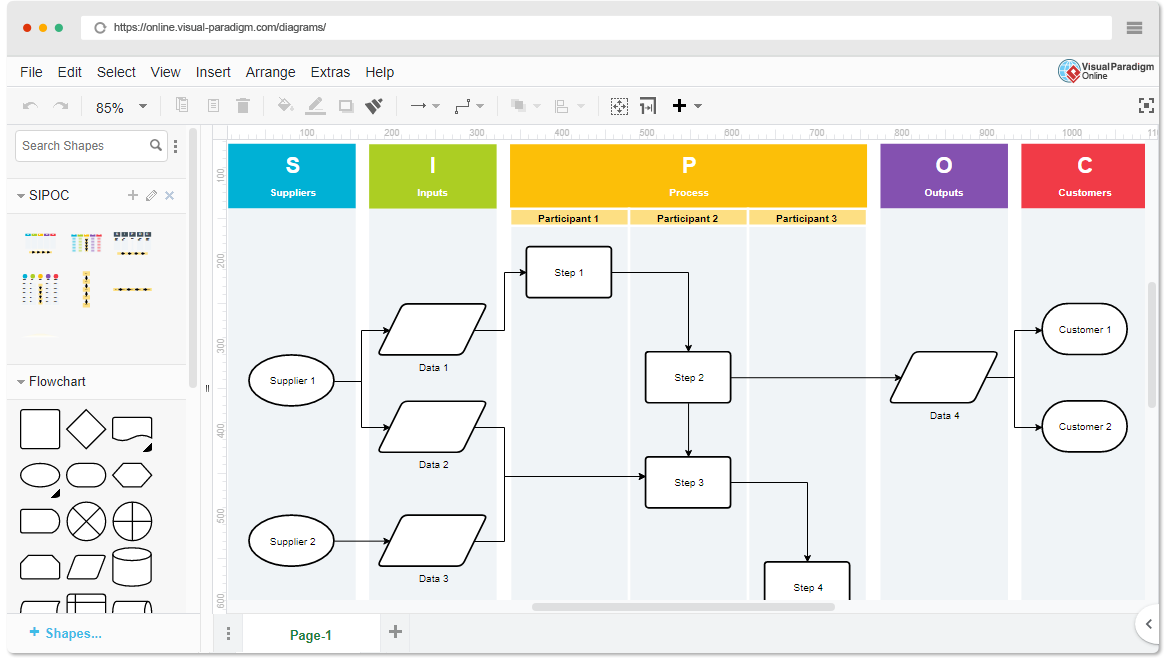

SIPOC is a high level management tool that simplifies the variables of any given process into five segments. SIPOC is the acronym of these five segments: S for suppliers, I for inputs, P for process, O for output and C for customers; A basic SIPOC diagram would look like this: Aside from managers, process improvement

What is a SIPOC (COPIS) Diagram? A SIPOC diagram documents an operation's Suppliers, Inputs, Process, Outputs, and Customers. A list of these elements helps to mark the boundaries of a process at a high level. The diagram provides the decision-makers with crucial information about the entire process without going into too much detail.

A SIPOC diagram is a potent tool for process design and improvement. SIPOC diagrams gained prominence as part of Total Quality Management (TQM) programs back in the '80s. Today, SIPOC diagrams are an essential part of Lean Six Sigma initiatives and part of the DMAIC cycle. DMAIC is a continuous improvement approach and stands for Define ...

What is the SIPOC model? SIPOC is a method to properly describe the transformation process within a company that offers products and/or services. It's a tool for process improvement that summarises the input and output of one or multiple processes in tables. The practice of applying this model is also referred to as process mapping.

A SIPOC table, or a SIPOC diagram, presents an excellent opportunity for teams, the higher management, and all stakeholders to troubleshoot process-related issues, and accordingly, develop appropriate strategies for improvements. Key Components of the SIPOC Model

SIPOC Diagram at a Glance A high-level process map that defines the scope of a process and its inputs, outputs, suppliers, and customers. Represents the flow of the process and its key elements in a table format. Widely used in process design and improvement initiatives. It helps identify relevant information before starting a project.

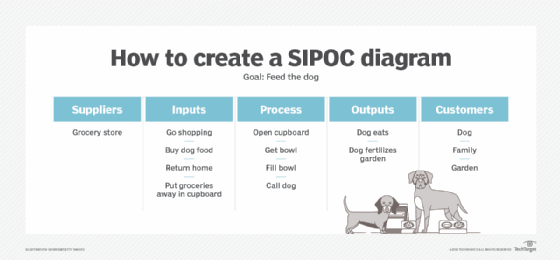

How to Create a SIPOC Diagram Making a diagram is simple; you can draw one by hand, use a pre-made template, or use a computer program to create a chart. Each column in this chart should represent the five abbreviations, in order: Suppliers, Inputs, Process, Outputs, and Customers.

SIPOC diagram is helpful for the business world as it provides the right options to prepare the documents of your project or process by using graphs, tables, pie charts, etc. SIPOC is the sum of five meaningful terms, Suppliers, Input, Process, Output, and customer, that helps you look into each term and find what you need to bring all of them ...

A Sipoc diagram is a detailed table that illustrates the inputs and outputs involved in a single process. The term SIPOC is an acronym for suppliers, inputs, process, output, and customers. Unlike your regular step-by-step chart, this diagram features a comprehensive list of elements involved in the process.

A SIPOC diagram is a tool used by a team to identify all relevant elements of a process improvement project before work begins. It helps define a complex project that may not be well scoped, and is typically employed at the Measure phase of the Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) methodology.

What is SIPOC? In six sigma, SIPOC is often used in the "Define" phase of DMAIC steps, as it helps clearly understand the purpose and the scope of a process.SIPOC shorts for suppliers, inputs, process, outputs and customers. As it is always completed by the sequence of process, outputs, customers, inputs, suppliers, sometimes it can also be known as POCIS diagram.

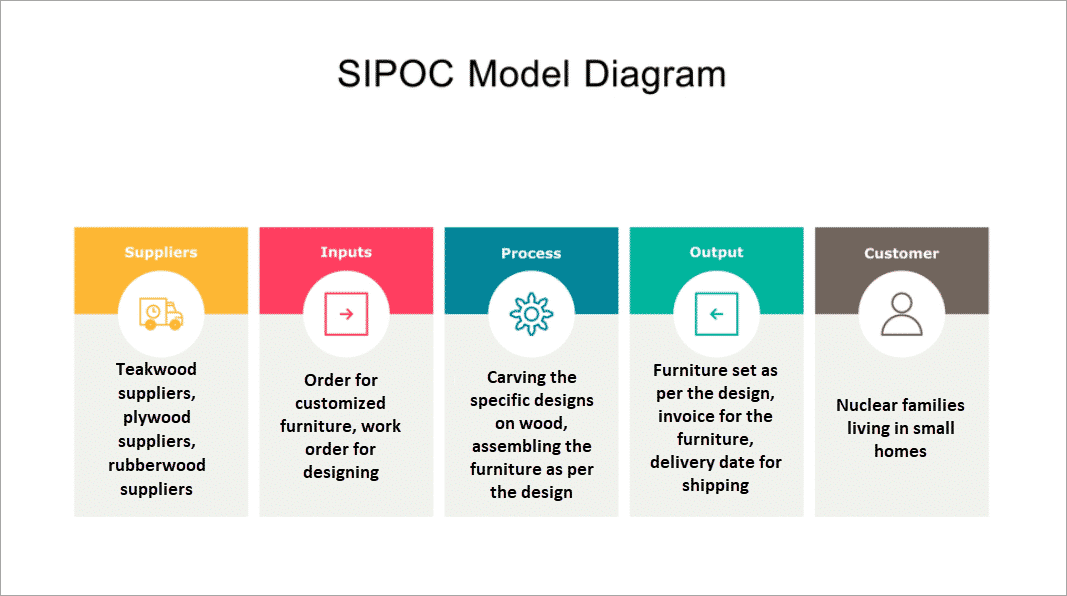

A SIPOC diagram(pronounced as sigh-pock), is a visual tool that is used to represent the end-to-end processes of a business model. It is a widely known six-sigma diagram that stands for Suppliers, Inputs, Process, Outputs, and Customers. It provides a high-level process modeling of the business by listing all these parameters in dedicated columns. A SIPOC map is mostly used to define the overall model of a business, analyze it, and further improve it. These are the 5 main entities that are used while creating a SIPOC diagram. 1. Suppliers:It represents any role, entity, or system that provides initial input. 2. Inputs: This can be anything that is consumed or processed in the system (and triggers a process). 3. Process: It is the foundation of the diagram and represents the overall structure followed by the business. 4. Outputs: Once the input is processed, it adds value to it, and ends up becoming an output (that can be an input to any other process). 5. Customers: They depict the...

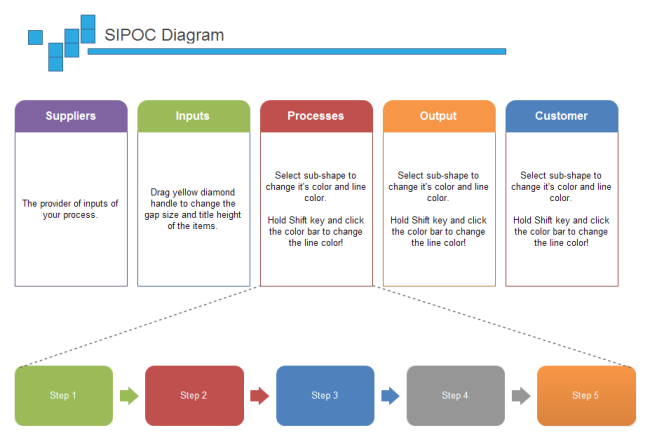

A SIPOC (say: sigh-pok) diagram is a simple way of recording an end-to-end business process. SIPOC stands for: Suppliers. Inputs. Process. Outputs. Customers. It's a visual process mapping technique, and it is used to create clarity before digging into the deeper levels of the business process.

The SIPOC diagram is a flowchart that represents the elements of SIPOC. Each process is matched against these elements for improvement before the project is undertaken. The SIPOC diagram helps in understanding each process from start to end prior to the implementation stage.

SIPOC Diagram. Creating a SIPOC diagram is best done in a team setting, following a specific sequence of steps: (1) Processes, (2) Outputs, (3) Customers, (4) Inputs, (5) Suppliers. This center-out approach works very well since most teams can quickly recite their work processes, but do not always know who their customers and suppliers are.

SIPOC is a high level process map and is explained here with a SIPOC diagram example. Learn how to create SIPOC for your project in 7 simple steps. SIPOC stands for Suppliers, Inputs, Process, Outputs and Customers. This is designed to be a high level process view with 6-7 process steps displayed.

The SIPOC Diagram is one of the Most Important tools in a Lean and/or Six Sigma project. This tool will help the team identify whether they have focused on the right process. The SIPOCR will also help the team to understand who their Customers are and what are their Requirements. Lean Six Sigma Green Belt Certification Training

SIPOC diagram is a Six Sigma tool used for documenting business processes. The word SIPOC stands for Suppliers, Inputs, Process, Outputs, and Customers which form the columns of the diagram. SIPOC diagram visually documents a business process from beginning to end. Because the diagram doesn’t contain much detail about the process, it is often called a high-level process map.

What is a SIPOC Diagram? SIPOC Diagram basically helps understand how a business process works by visualising it. Typically, it is in a tabular form with separate columns for each element. Information regarding the roles, responsibilities, and standards are outlined in the diagram.

0 Response to "40 what is a sipoc diagram"

Post a Comment