38 stainless steel phase diagram

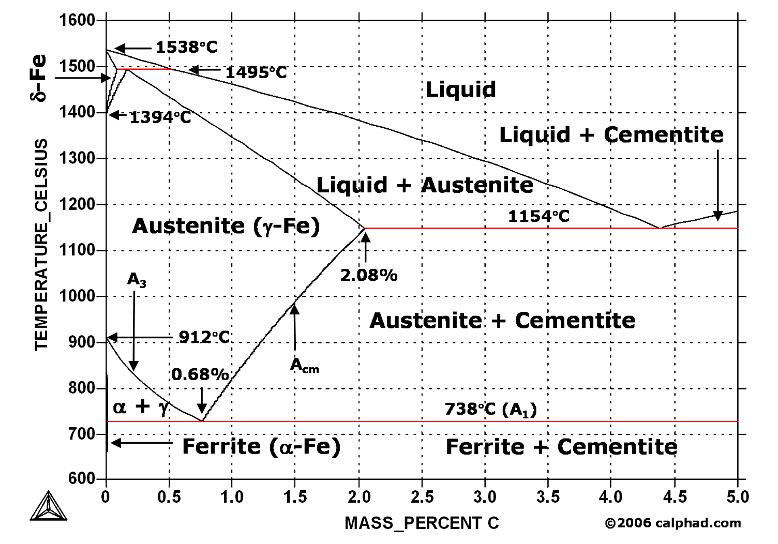

Iron-carbon phase diagram describes the iron-carbon system of alloys containing up to 6.67% of carbon, discloses the phases Cementite is a hard and brittle substance, influencing on the properties of steels and cast irons. The following phase transformations occur with iron-carbon alloys phase in stainless steels is presented. In the second section, the properties effect, prediction method, processing effect, elemental addition, retardation method and Thermo-Calc -austenite when the aging time was high; they constructed a schematic diagram to explain the precipitation behavior of the. .

Hi /r/askengineers! I've been working in the polymers industry as a process engineer for some time now, and I'm beginning to take on some design roles that I feel would traditionally be held by mechanical/materials engineers. In short, I'm looking to learn the practical aspects of material choices in industrial applications. Emphasis on practical. In other words, I want to be able to answer questions like: What are the tradeoffs of making this part out of aluminum instead of steel (what am I s...

Stainless steel phase diagram

**Superalloys in Jet Engines:** [Jet engines were first developed in Germany](http://i.imgur.com/L0Ajp.png) around 1938-1945 (okay, there were designs drawn centuries earlier, and apparently there were a few models made in the twenties, but this is where they picked up according to [wiki article](http://en.wikipedia.org/wiki/Jet_engine#History)). The previous image is of the ME-262 which could fly 11.5 km high at 870 kph. The key to high efficiency and power was the high combustion zone temperat... Free download DIAGRAM 316 Stainless Steel Phase Diagram, Stainless Steel Brazing on Graphite Fixtures, The steel phase diagram Download Scientific Diagram, Stainless Steels, 1 Phase diagram of Stainless Steel Alloys 33 Download, 30 Ternary phase diagram for FeCrNi stainless... Steel and Cast Iron Defined. Iron-Carbon Phase Diagram. § In addition to corrosion resistance, stainless steels are noted for their combination of strength and ductility § While desirable in many applications, these properties generally make stainless steel difficult to work in manufacturing.

Stainless steel phase diagram. **Theory and tips on white LEDs and grow lights** last update: 8 July 2021 I wanted to try writing stuff a bit different so I used bullet points with short and direct statements. There's a bit of theory below but actual white light theory would require its own article due to the 40,000 character limit in a post. * [part of SAG's plant lighting guide](https://www.reddit.com/r/HandsOnComplexity/comments/17nxhd/sags_plant_lighting_guide_linked_together/) * [Using a lux meter as a plant light me... Stainless steel grades, composition, molecular structure, production, and properties. The Chicago Cloud Gate sculpture retains its shiny luster thanks to On the iron-carbon phase diagram this lattice is normally found at high temperatures. However, adding nickel and/or manganese allows austenite to... Chapter 14: Phase Diagram Applications / 293. Austenitic Stainless Steel. In connection with a research project aimed at the conservation of Two examples of the application of phase diagrams to alloy design are discussed: alloy additions to a hacksaw blade steel to allow the production. No phase diagram is more important to materials scientists than the Fe-C phase diagram because it allows us to explain many of the different types of steels.

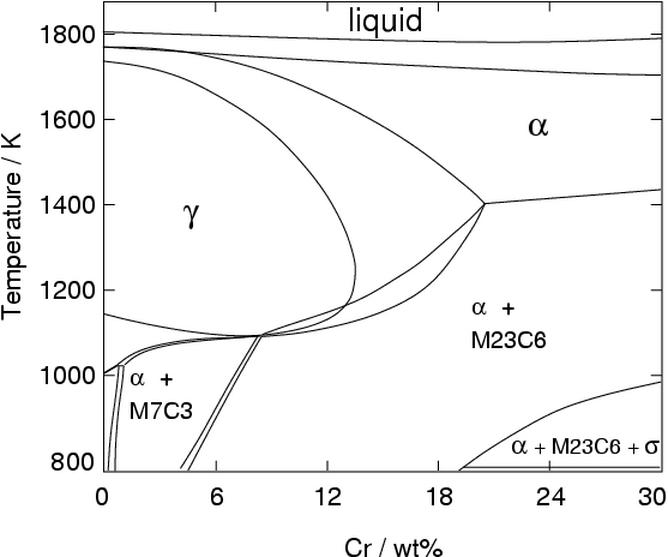

I could use some help. I wanted to make my own Freeze Dryer. I'm able to source all the materials for the dyer for under let's say $250, $300 including tax, shipping, etc.. one component of the freeze dryer that I haven't been able to figure out is the vapor trap, aka vapor condenser, aka cold trap, aka vapor concentrator, etc.... The vapor trap needs to get to get to less than - 50c according to the water sublimation chart. [https://en.wikipedia.org/wiki/Triple\_point#/media/File:Phase\_d... HI! MY Name is Abdullah! Today I'LL tell you about A **caliper** ([British spelling](https://en.wikipedia.org/wiki/American_and_British_English_spelling_differences) also **calliper**, or in [plurale tantum](https://en.wikipedia.org/wiki/Plurale_tantum) sense **a pair of calipers**) is a device used to [measure](https://en.wikipedia.org/wiki/Measurement) the dimensions of an object. caliper. Many types of calipers permit reading out a measurement on a ruled scale, a dial, or a digital display.... Chapter 6. Phase Diagrams. Many of the engineering materials possess mixtures of phases, e.g. steel, paints, and composites. The mixture of two or more phases may permit interaction between different phases, and results in properties usually are different from the properties of individual phases. And the base phase diagram in stainless steel is the iron-chromium binary phase diagram. In the phase diagram, you can understand that at specific temperature and chemical composition, we can predict the phases the alloy can contain.

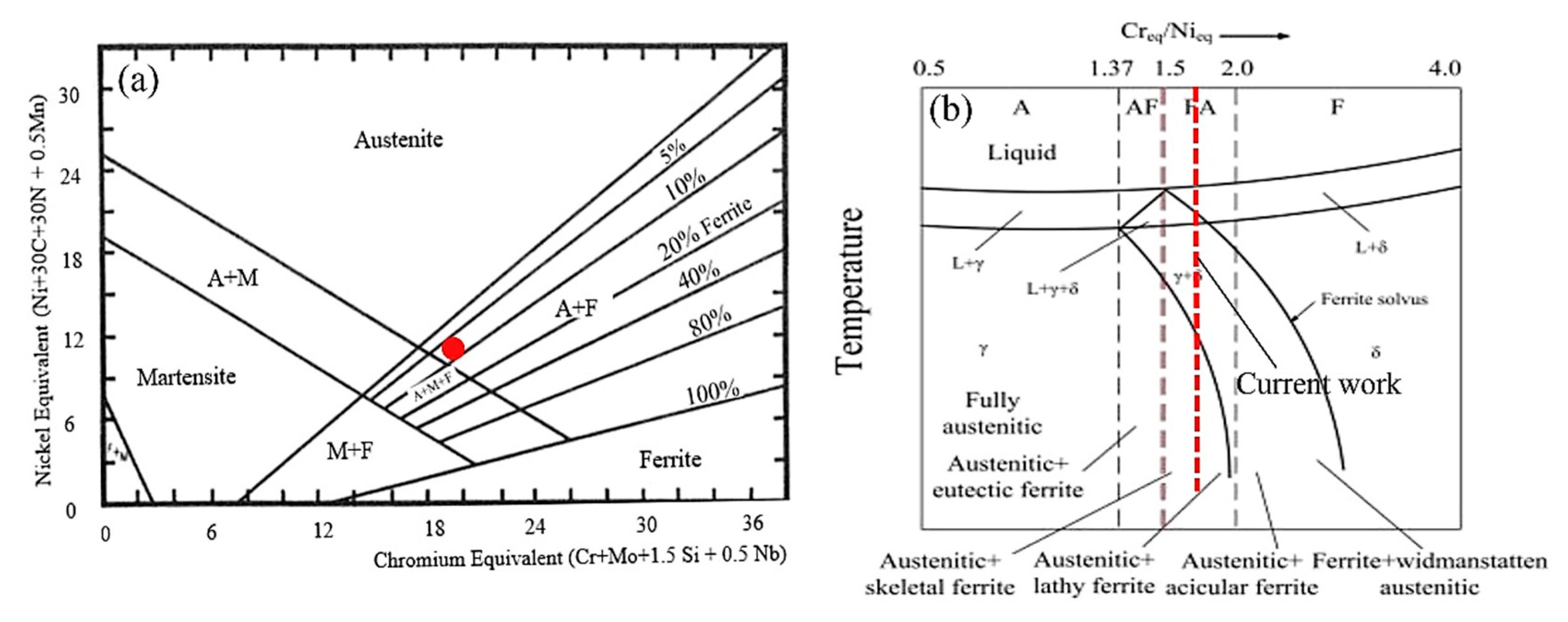

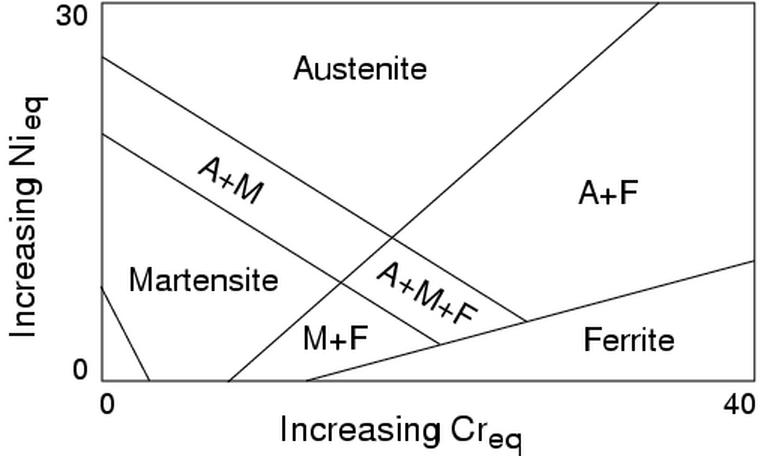

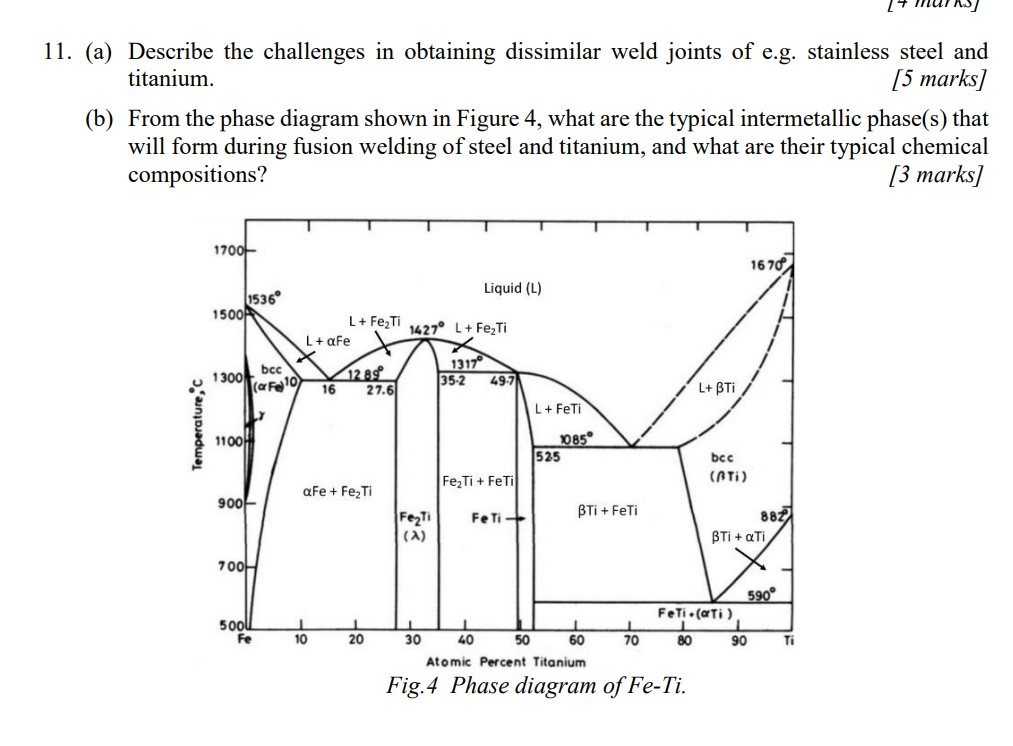

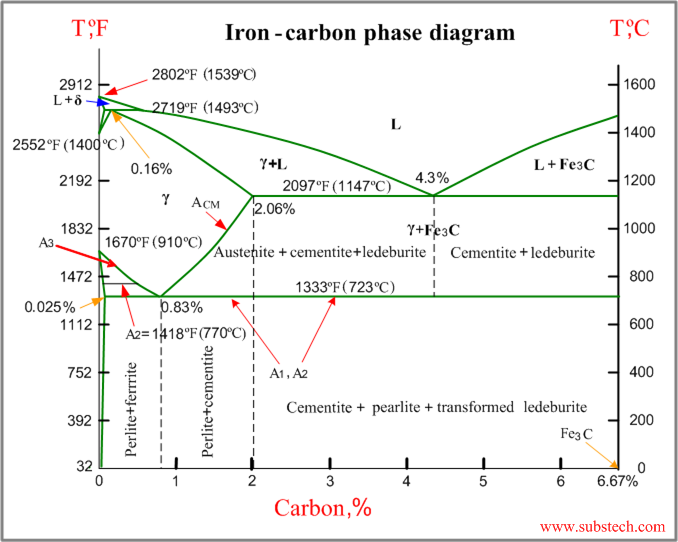

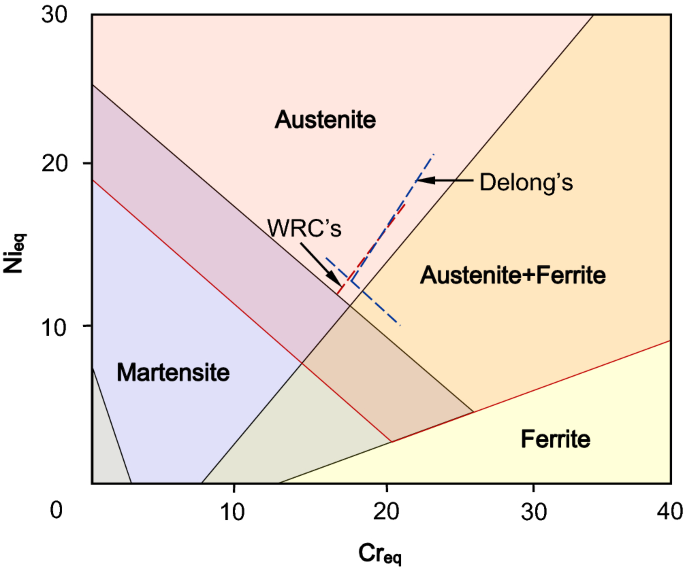

Steels and stainless steels are the most commonly used metals currently in the world. They are favoured in a wide area of applications due to their properties such as Influence of gadolinium on the microstructure and mechanical properties of steel. Figure 2—Fe-Gd binary phase diagram7. Table I. Chapter 5. Steel - Phase Diagram. PNGUOT-Civil Engineering Department Chapter 5. Steel - Phase Diagram. Generally in order to increase the strength of steel other alloying elements are added which increase the strength while retaining toughness and ductility. 2.2.4 duplex stainless steel. These steels contain a mixture of ferrite and austenite phases at room temperature in order to combine the beneficial The composition of stainless steel can be related to its non-equilibrium metallurgical structure by means of a Schaeffler diagram [16], which... (C<0.008wt%) † Stainless steel Example: Phase Equilibria. For a 99.6 wt% Fe-0.40 wt% C at a temperature just below the eutectoid, determine the following.

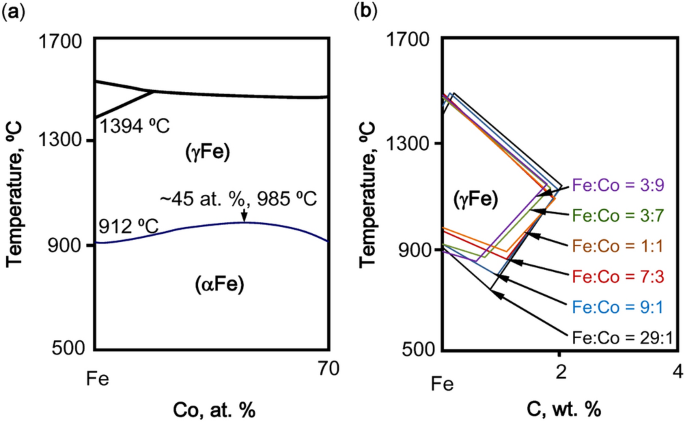

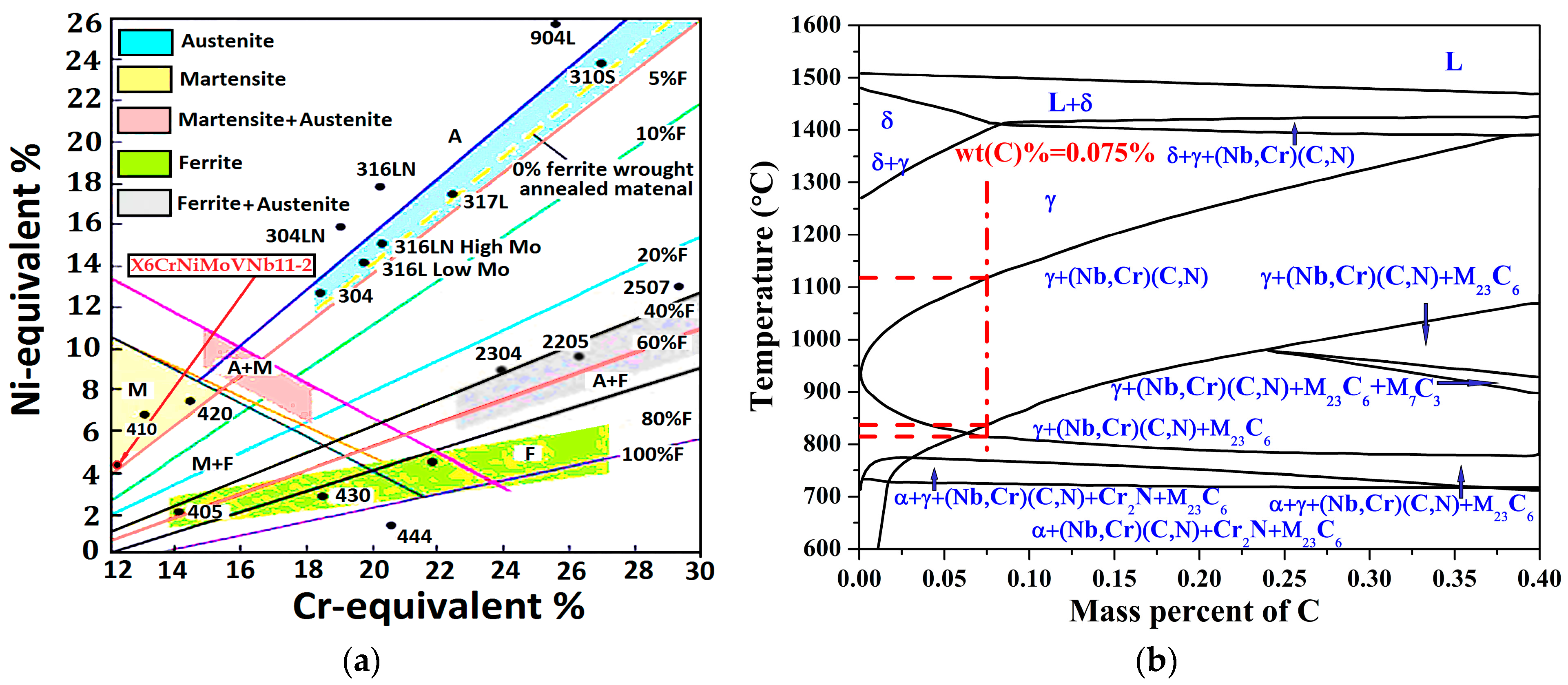

austenitic stainless steel (AISI304LN) and duplex. stainless steel (SAF 2205) as relevant representatives. of stainless steels were conducted. different approaches of calculation of phase diagram: using complete chemical composition or using. calculated nickel and chromium equivalent.

Hello everyone, I am working on a project with a Precipitation Hardening Stainless Steel (17-4PH) and I am following the ASTM standard regarding H1150/H1150D aging heat treatments. In accordance to the above, I would like to find someone who has the knowledge and access in the appropriate databases and tools, in order to provide me with the necessary phase diagrams for the steel, with TTT and CCT curves, with phase volume diagram and with the precipitation sequence diagram. Ideal...

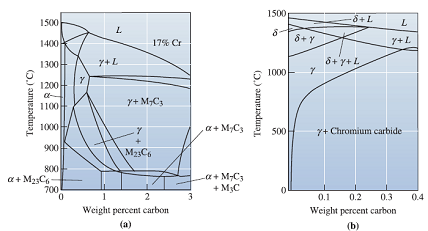

To qualify as stainless steel, Fe-base alloys must contain at least 10.5%Cr. The Iron-Chromium phase diagram shows that up to about 13%Cr, the steel undergoes successive transfomations upon cooling from the liquid phase from ferritic α phase to austenitic γ phase and back to α...

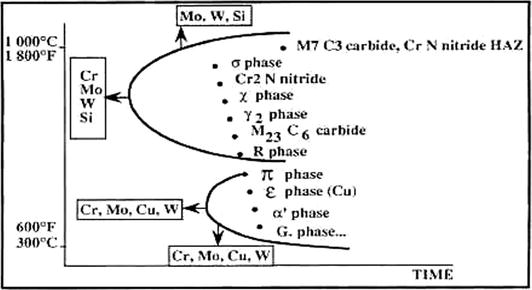

Phase Equilibria. Main Phases. The designation stainless steelimplies little more than a 12% Cr content. Most of the stainless steels are based on the Fe-Cr-C and Figure 7: Schaeffler diagram for weld metals. Precipitate Phases. These include carbides, nitrides or intermetallic compounds.

Liquid Phase Bonding of 316L Stainless Steel to AZ31. 1 Binary equilibrium phase diagrams: (a) Mg-Cu; (b) Mg-Ni samples were cut from an extruded rod of 10 mm in diameter to disks of 5 mm in thickness.

1.5.5 Phase Diagrams Containing Intermediate Phases. 1.5.6 The Gibbs Phase Rule 1.5.7 The Effect of Temperature on Solid Solubility. 4.7.1 Casting of Carbon and Low-Alloy Steels 4.7.2 Casting of High-Speed Steels 4.7.3 Stainless Steel WeId Metal.

FactSage 8.1 - List of Stored Phase Diagrams (7811). FACT Databases. FScopp copper alloy data (422). FSlead lead alloy data (161). FSstel steel alloy data (304). FSupsi ultrapure silicon data (0). SGTE Databases.

&#x200B; It is strongly recommended that you start a book "crazy science" to increase your knowledge. There are PDF arc melting in plasma arc cutting plasma cutting with different working gases can cut all kinds of metals difficult to cut by oxygen, especially for colored metals (stainless steel, aluminum, copper, titanium, nickel). Its main advantages are that When cutting the metal with small thickness, the plasma cutting speed is fast, especially when cutting ordi...

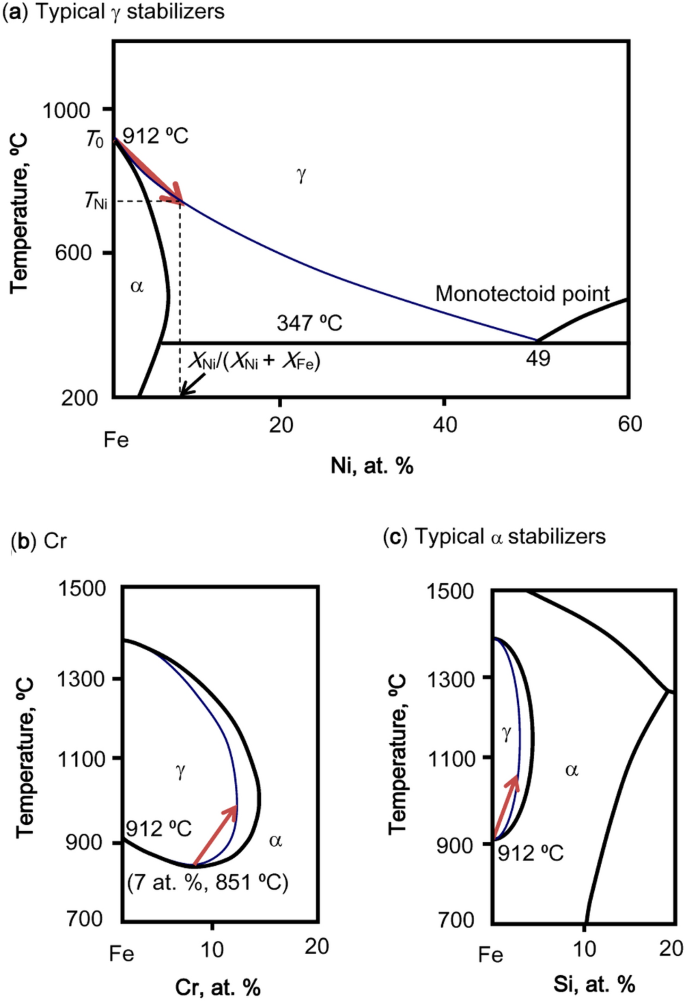

Austenite, also known as gamma-phase iron (γ-Fe), is a metallic, non-magnetic allotrope of iron or a solid solution of iron, with an alloying element. In plain-carbon steel, austenite exists above the critical eutectoid temperature of 1000 K (727 °C); other alloys of steel have different eutectoid temperatures.

Полезно? Из урока. Stainless steels. Introduction and classification12:06. Phase diagrams and microstructure13:44.

So I'm making some straight razors as my own little project and I have my colleges machine and CNC shop available to me. I've planned out most of the other processes but I need to figure out the heat treatment process before going any further. I've used McMaster Carr to narrow down what stainless steels to choose from. After some research it seems that 440c stainless would be the best for it's use (perhaps a little overkill but I don't know a better suited alternative that can be heat hardened ...

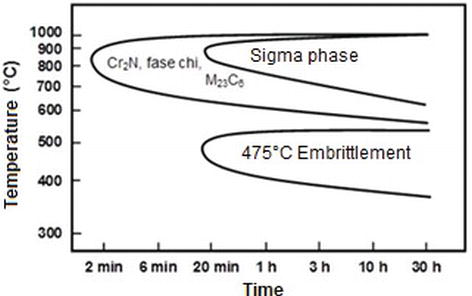

2 When speaking of stainless steels, the phase α, corresponding to the ferritic structure, is often alternatively referred to as phase δ. The distinction On the same Fe-Cr phase diagram, there exists phase α': this phase forms at temperatures ranging from approximately 350°C to 550°C for hold times...

Key words: CALPHAD, Stainless Steel, Phase diagram, Computational Thermodynamics. 1. Introduction. The stainless steels are in technological sense of a great importance due to their unique properties which can be taken advantage in a wide variety of applications.

Austenitic stainless steels are employed in many industrial fields, due to their excellent corrosion resistance, easy formability and weldability. In this review the main studies on the formation and characteristics of S phase are summarized and the results of the more recent research are also...

Hello everyone, I am working on a project with a Precipitation Hardening Stainless Steel (17-4PH) and I am following the ASTM standard regarding H1150/H1150D aging heat treatments. In accordance to the above, I would like to find someone who has the knowledge and access in the appropriate databases and tools, in order to provide me with the necessary phase diagrams for the steel, with TTT and CCT curves, with phase volume diagram and with the precipitation sequence diagram. Ideal soft...

Phase Diagram Of Stainless Steel. What Is The Difference Between High Carbon Steel And. Figure 2 From Microstructure Evolution And Solidification. Phase Diagram Of Stainless Steel. Lean Duplex Stainless Steel Total Materia Article. Applied Sciences.

304l stainless steel phase diagram. (PDF) Considerations for the weldability of types 304L and. p>This work is a contribution study of the heat-affected zone in the real welded joint of stainless steel 304L. This zone was compared to the heat-affected zone obtained by using a thermal cycle.

**[Nickel Rundown:](http://i.imgur.com/nbMr8.png)** Valence: +2 Crystal Structure: [FCC](http://cst-www.nrl.navy.mil/lattice/struk/a1.html ) Density: 8.91 g/cc Melting Point: 1455^o C Thermal Conductivity: 89 W/m-K Elastic Modulus: 200 GPa Coefficient of Thermal Expansion: 13.3 microns/^o C Electrical Resistivity: 6.84 micro Ohms-cm Cost: $11/kg Ni superalloys are similar to Co superalloys, and are used for [combustion zone turbine blades](http://www.tradenote.net/images/users/000/483/...

A ternary phase diagram has three components. The three components are usually compositions of elements, but may include temperature or pressure also. Ternary phase diagrams are needed so that three components can be compared at once. For example, stainless steel has iron, nickel, and...

The welding process of stainless steels by laser sources, in relation with his diagram showed that his map can be applied in new welding operations. The recognition of the crystalline phases (austenite, ferrite, martensite, possible carbides precipitated on cool-ing), was then interpreted by the well-known...

Phase diagrams are graphical representations of the phases present in an alloy at different The iron-carbon phase diagram is widely used to understand the different phases of steel and cast iron. This iron carbon phase diagram is plotted with the carbon concentrations by weight on the X-axis and...

**Author**: u/DrPronFlex(**Karma:** 269, **Created:** Jan-2021). [**Tripping and Twipping, DD about steel (the metal) part 2 includes stainless on r/vitards**](https://www.reddit.com/r/vitards/comments/ncy4v7) -------------------------- [PICTURES DETECTED: this DD post is better viewed in it's original post](https://www.reddit.com/r/vitards/comments/ncy4v7) **Tripping and Twipping, DD about steel part 2, includes stainless** Thanks for all the rewards and appreciation about the first D...

Category: 304 stainless steel phase diagram Show details. Phase Diagrams - DT Online. 9 hours ago Phase Diagram for Carbon Steel. As Carbon Steels are heated towards their melting point their Crystalline Structures change from a Body Centred Cubic structure to a Face Centred Cubic structure.

Steel and Cast Iron Defined. Iron-Carbon Phase Diagram. § In addition to corrosion resistance, stainless steels are noted for their combination of strength and ductility § While desirable in many applications, these properties generally make stainless steel difficult to work in manufacturing.

Free download DIAGRAM 316 Stainless Steel Phase Diagram, Stainless Steel Brazing on Graphite Fixtures, The steel phase diagram Download Scientific Diagram, Stainless Steels, 1 Phase diagram of Stainless Steel Alloys 33 Download, 30 Ternary phase diagram for FeCrNi stainless...

**Superalloys in Jet Engines:** [Jet engines were first developed in Germany](http://i.imgur.com/L0Ajp.png) around 1938-1945 (okay, there were designs drawn centuries earlier, and apparently there were a few models made in the twenties, but this is where they picked up according to [wiki article](http://en.wikipedia.org/wiki/Jet_engine#History)). The previous image is of the ME-262 which could fly 11.5 km high at 870 kph. The key to high efficiency and power was the high combustion zone temperat...

0 Response to "38 stainless steel phase diagram"

Post a Comment