37 copper zinc phase diagram

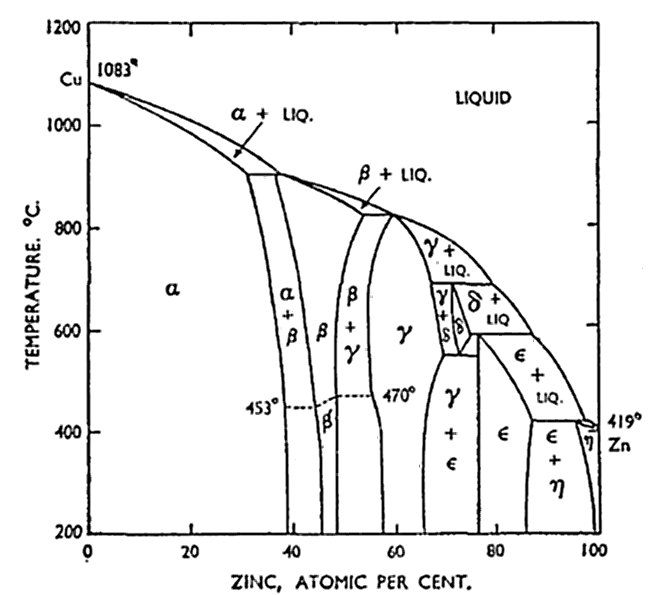

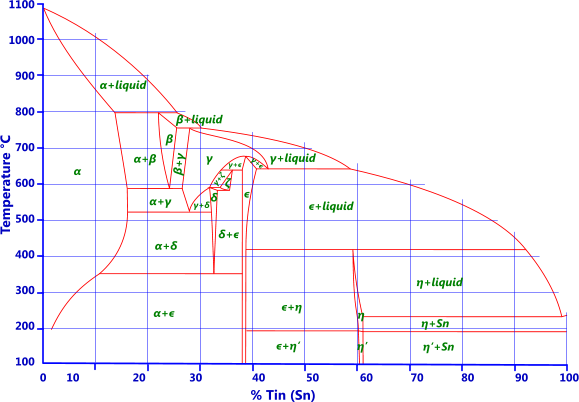

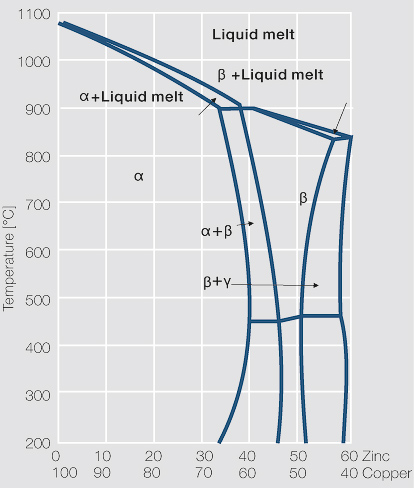

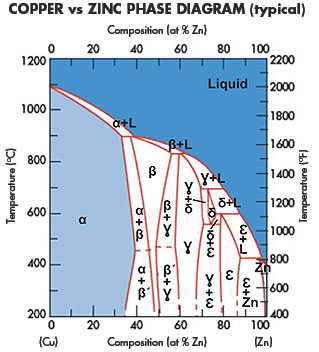

The copper-zinc phase diagram shown in Fig. 9.2 contains intermedi-ate phases with appreciable ranges of solid solubility. In this diagram, the copper-rich α solid solution and the zinc-rich η solid solution are the two terminal phases, and the four intermediate phases are β, γ, δ, and ε. The Phase Diagrams • Indicate phases as function of T, Co, and P. • For this course:-binary systems: just 2 components.-independent variables: T and Co (P = 1 atm is almost always used). • Phase Diagram for Cu-Ni system Adapted from Fig. 9.3(a), Callister 7e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys , P. Nash

Copper-Zinc Binary Alloy Phase Diagram (based on 1912 Carpenter H.C.H.). Author: Carpenter H.C.H. | Document Download | Product code: ZAPD-CU-ZN-103268.

Copper zinc phase diagram

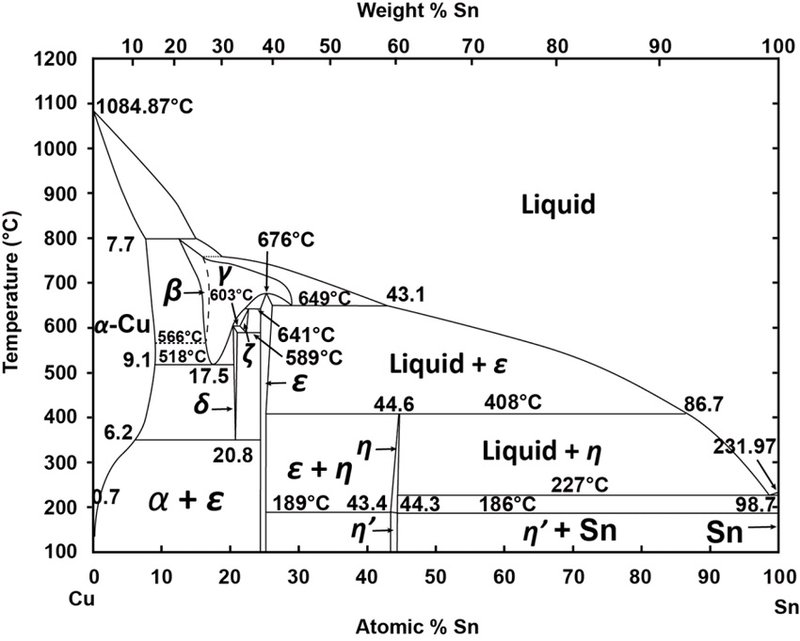

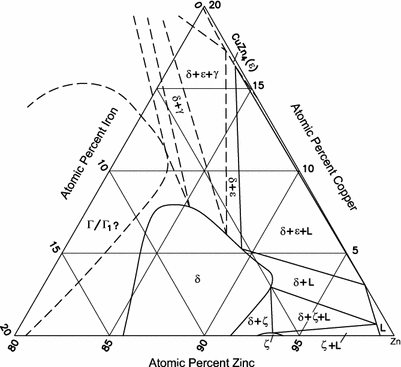

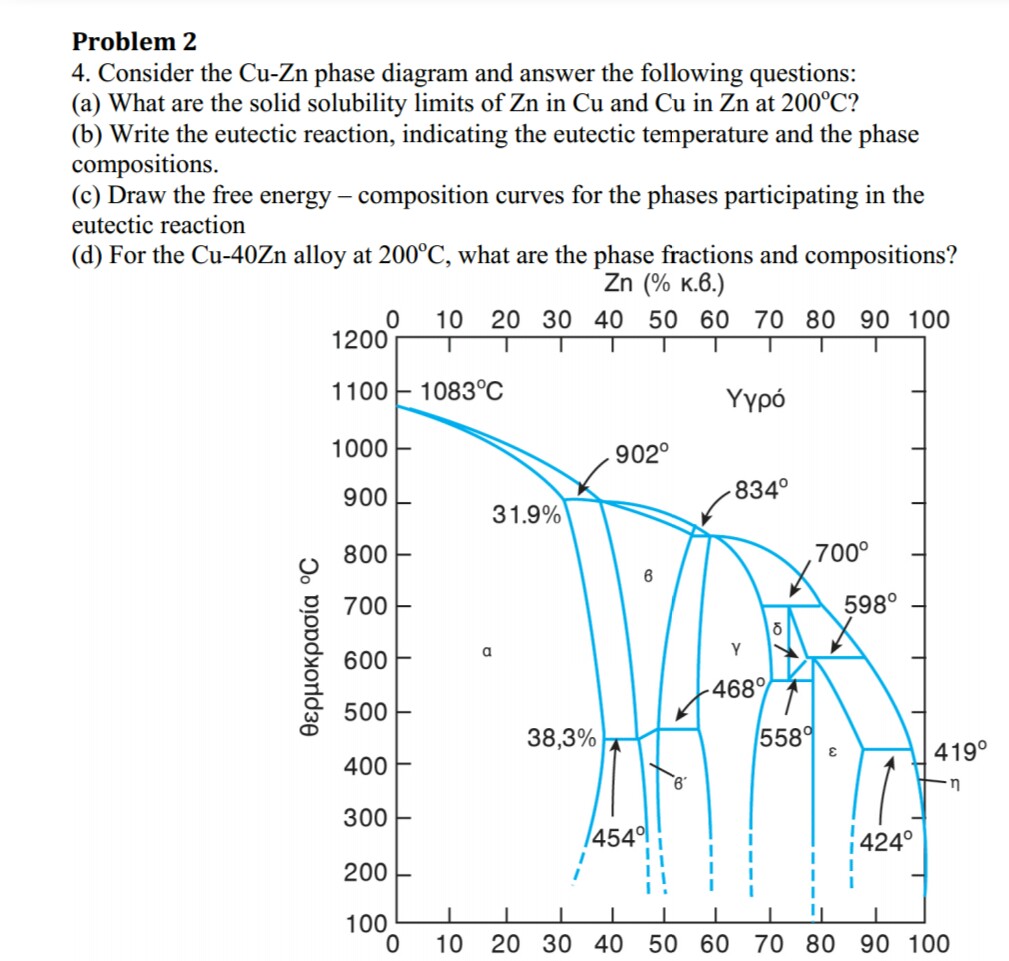

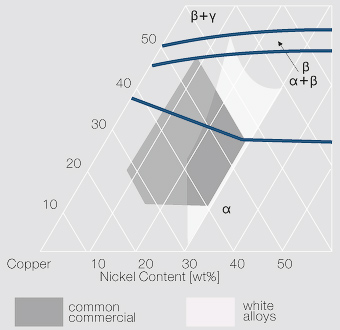

Abstract. This article is a compilation of ternary alloy phase diagrams for which copper (Cu) is the first-named element in the ternary system. The other elements are Fe, Mn, Ni, Pb, S, Sb, Si, Sn, Ti and Zn. The diagrams are presented with element compositions in weight percent. The article includes 42 phase diagrams (liquidus projection ... The Copper (Cu) - Zinc (Zn) equilibrium phase diagram for 200g Cu-54wt% Zn alloy and 300g Cu -80wt% Zn is given in Figure 1. The temperature at Point A and Point C are just above 900 °C and 600°C, respectively. Metal Casting Processes Casting Solidification of Pure Metals Solidification of Pure Metals Solid Solution Alloys Solidification of Solid Solution Alloys Nickel-Copper Alloy Phase Diagram Mechanical Properties of Copper-Nickel and Copper-Zinc Alloys Solidification of Solid Solution Alloys Solidification of Eutectic Alloy Systems Lead-Tin Phase Diagram Iron-Iron Carbide Phase Diagram ...

Copper zinc phase diagram. Commercial brasses are copper-rich copper-zinc alloys. For example, cartridge brass is 70 wt% copper-30 wt% zinc 15 16 The magnesium-lead phase diagram: like two simple eutectic diagrams joined back to back Intermetallic compound (with distinct chemical formula), NOT a solid solution. phase diagrams for pure materials; (3) the interpretation of phase diagrams; (4) ... For example, in a copper-zinc brass, the components are Cu and Zn.Solute and sol-vent, which are also common terms, were defined in Section 4.3.Another term used in this context is system,which has two meanings. The Diagram of Cu-Si-Zn Alloy-II, Technol. Rep. Osaka Univ., Vol. 7, 1957, p 385-397 Reviewed under the auspices of the Alloy Phase Diagram International Commission. Document includes crystal data for the Copper-Silicon-Zinc system, allotropic transformation data, and related references. β exist at extremities of phase diagram Intermediate solid solutions: phases found at locations other than the extremes Copper-zinc system: six different solid solutions Dashed lines indicate indetermination of data (temperatures too low and reaction times too long) Each region is still limited to two phases

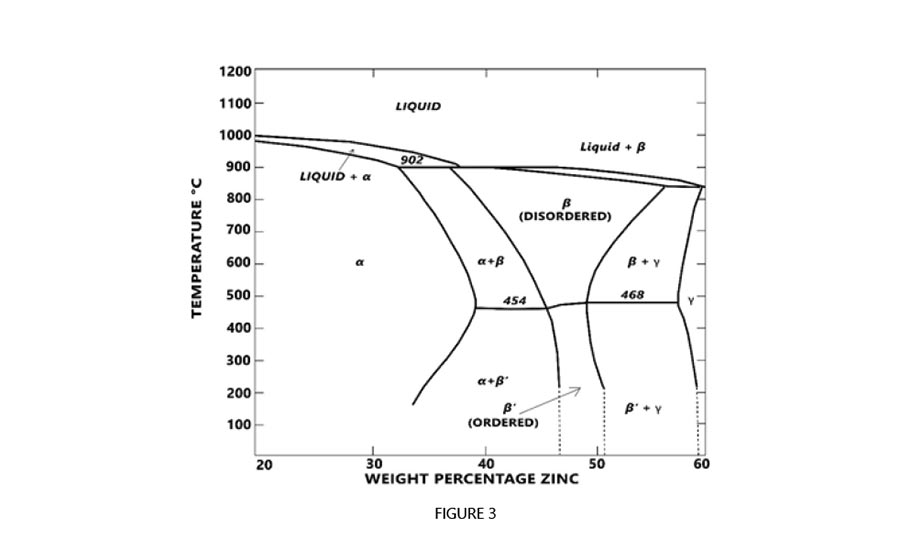

Some Phase Diagrams. The colored regions show typical bronze compositions. That doesn't look so simple, especially at the copper-rich side where we will find the "common" bronzes as indicated. It is definitely more complicated than the iron -carbon phase diagram that exercised us so much already. Here is the copper (Cu) - zinc (Zn) phase diagram. Download scientific diagram | Copper Zinc Phase diagram (I. Macleod after Lyman et al. 1973). from publication: Preliminary analysis of copper alloy fastenings from an unidentified shipwreck in ... A region of the copper-zinc phase diagram that has been enlarged to show eutectoid and peritectic invariant points , C, 74 wt% Zn) and P (598 C, 78.6 wt% Zn), respectively. Figure by MIT OCW. Note that each single-phase field is separated from other single-phase fields by a two-phase field. Lecture 19 – Binary phase diagrams 6 of 16 11/23/05 E.10 The phase diagram for the copper-zinc system (which includes brasses) is shown in Figure GL2.19. Use the diagram to answer the following questions. (a) (i) Shade the single-phase regions. (ii) Highlight the eutectoid point and five peritectic points in the copper-zinc system, and write down their compositions and temperatures.

The copper-zinc phase diagram: Terminal and Intermediate Solid Solutions. Terminal solid solutions. intermediate solid solutions. Commercial brasses are copper-rich copper-zinc alloys. For example, cartridge brass is 70 wt% copper-30 wt% zinc Chapter 9- 15 The magnesium-lead phase diagram: like two simple eutectic diagrams joined back to back Melting temperature of Mg2Pb 550 oC) Constitutional Diagram of the Copper-Zinc Alloys The addition of zinc to copper results in the formation of a series of solid solutions which, in accordance with usual practice, are referred to in order of diminishing copper content as the a, b, g, etc., constituents. The diagram may be summarized as follows: Jan 15, 2016 · It is 19 wt% Mg-81 wt% Pb. Melting temperature of Mg2Pb 550 oC) Extensive solubility. of the phase diagrams. Eutectic transformation also called eutectic reaction. A eutectic reaction is an invariant reaction, and a eutectic point is also called an invariant point. the horizontal tie line at the eutectoid temperature is termed a eutectoid isotherm. Here are a number of highest rated Copper Zinc Phase Diagram pictures on internet. We identified it from reliable source. Its submitted by admin in the best field. We give a positive response this nice of Copper Zinc Phase Diagram graphic could possibly be the most trending subject next we share it in google benefit or facebook.

This representation is called a phase diagram. The phase diagrams of some binary systems relevant to bronze show the behavior of alloying elements that typically results in one of the three cases mentioned previously. The copper-tin equilibrium phase diagram (Figure 3) illustrates Cases (1) and (2).

system, the phase diagram usually has the general appearance of that shown in Fig. 3. The diagram consists of two single-phase fields separated by a two-phase field. The boundary between the liquid field and the two-phase field in Fig. 3 is called the liquidus; that between the two-phase field and solid field is the solidus.

Zinc is one of the most widely used alloying elements in Cu alloys, thus diffusion coefficients in both the solid solution and intermetallic phases in the Cu-Zn system and the Cu-Zn binary phase diagram are essential for understanding the kinetics and phase stability of Cu alloys.

Download scientific diagram | Phase diagram of the copper–zinc system [17]. from publication: Cu-Zn powders as potential Cr(VI) adsorbents for drinking water | This work examines the possibility ...

From the copper-zinc phase diagram we can see the solid solubility of zinc in copper, for concentrations of zinc upto about 30 at.%, at equilibrium the alloy should be of a single phase. Alpha brasses are often seen with a single phase, however this usually arises due to annealing.

Phase Diagrams Brass · The Copper-Zincbinary phase diagram (brass) is another example of a complex phase diagram which shows many invariant reactions. · Two common alloy compositions are shown, Cartridge brass (red) which is Cu-30 wt % Zn, and Muntz metal (green) Cu-40 wt % Zn. From:

Teach Yourself Phase Diagrams A.1 HRS 03/11/2009 and Phase Transformations ... concentrations of copper and zinc in the -brass, in at%, X Cu and X Zn. E.2 A special brazing alloy contains 63 wt% gold (Au) and 37wt% nickel (Ni) (which is written Au-37wt% Ni). The atomic weight of Au (197.0) is more than three times that of Ni (58.7).

nglos324 - brass Brass, Cartridge Brass, Muntz Metal Index Brass is a series of binary alloys between copper and zinc, with an upper zinc content of about 50 wt %. The phase diagram is shown, and two brasses are identified. Cartridge brass has the composition Cu-30 wt % Zn (green line) and Muntz metal Cu-40 wt % Zn (red line).

Zinc •"Zinc, in commerce also spelter, is a chemical element with symbol Zn and atomic number 30. It is the first element of group 12 of the periodic table. In some respects zinc is chemically similar to magnesium: its ion is of similar size and its only common oxidation state is +2. Zinc is the 24th most abundant element in the

possible high-pressure phase transitions at room temperature in the copper-zinc alloy system are proposed. The results indicate that the a phase above about.9: kb and 30 weight percent zinc transforms to a phase not existing at atmospheric pressure. The 0 and J3\ phases transform to the C2 phase at high pressures; there appears to be an

Metal Casting Processes Casting Solidification of Pure Metals Solidification of Pure Metals Solid Solution Alloys Solidification of Solid Solution Alloys Nickel-Copper Alloy Phase Diagram Mechanical Properties of Copper-Nickel and Copper-Zinc Alloys Solidification of Solid Solution Alloys Solidification of Eutectic Alloy Systems Lead-Tin Phase Diagram Iron-Iron Carbide Phase Diagram ...

The Copper (Cu) - Zinc (Zn) equilibrium phase diagram for 200g Cu-54wt% Zn alloy and 300g Cu -80wt% Zn is given in Figure 1. The temperature at Point A and Point C are just above 900 °C and 600°C, respectively.

Abstract. This article is a compilation of ternary alloy phase diagrams for which copper (Cu) is the first-named element in the ternary system. The other elements are Fe, Mn, Ni, Pb, S, Sb, Si, Sn, Ti and Zn. The diagrams are presented with element compositions in weight percent. The article includes 42 phase diagrams (liquidus projection ...

![Equilibrium Cu-Zn phase diagram [5] | Download Scientific Diagram](https://www.researchgate.net/profile/Pavel-Kejzlar/publication/316598481/figure/fig2/AS:616354306588689@1523961726879/Equilibrium-Cu-Zn-phase-diagram-5.png)

0 Response to "37 copper zinc phase diagram"

Post a Comment